CCTV AI Safety Systems for Workplace Visibility

- John Buttery

- Dec 7, 2025

- 7 min read

In every modern industrial facility, safety teams work incredibly hard, yet serious injuries continue to occur. Forklift-pedestrian near misses, line-of-travel violations, blocked aisles, and unsafe loading practices all hide in the blind spots between manual audits. Even the best EHS forklift safety systems struggle with one fundamental truth:

You cannot prevent what you cannot see.

For decades, organizations have tried to close this visibility gap with solutions like forklift pedestrian detection systems, RFID-based forklift proximity warning systems, and on-vehicle collision avoidance devices. These tools are valuable, but each covers only a fraction of real-world risk.

Today, that is changing.

A new category of technology, CCTV AI Safety Systems, is turning existing security cameras into real-time safety intelligence platforms. These systems detect unsafe conditions, analyze behavior, score risk, and help teams correct issues before they escalate into serious injuries or SIFs.

And for many organizations, this gives them unprecedented insight into what's happening on their floor.

"Blind spots don't cause incidents: unseen risk does. And AI safety platforms now shine a light on what humans can't always catch," according to Riodatos.

Why Serious Injuries Still Happen

Even in Strong Safety Programs, Hidden risk is everywhere

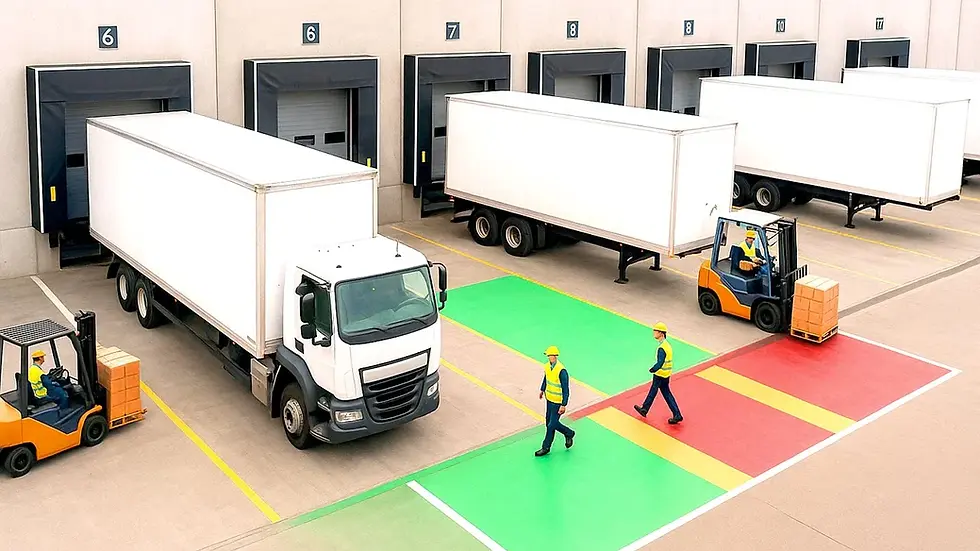

Walk into any warehouse, distribution center, or manufacturing floor, and you'll find a fast-moving environment. Forklifts maneuver through aisles, teams work around loading docks, and temporary labor moves in and out of high-risk zones. Supervisors cannot monitor every intersection and every task.

Manual audits catch what's visible in the moment and nothing more.

Critical risks happen between those observations:

A pedestrian cuts across an active loading zone.

A forklift backs into a blind corner.

PPE is forgotten during a busy shift.

Congestion builds around docks.

A worker takes the quickest path instead of the safest.

Most precursors to SIFs go completely unseen.

Lagging indicators keep everyone reactive

Incident logs, near-miss reports, and shift summaries come after the risk has occurred. By then, behavior patterns are entrenched, and root causes remain unclear.

Workplace risk has outpaced traditional visibility. Human limitations are not moral failures. Workers are not careless — they're human. Humans take shortcuts. Humans get busy. Humans become complacent. Without continuous visibility, risk builds silently.

Why CCTV AI Safety Systems

Becoming the New Standard in Industrial Safety

Unlike forklift proximity warning systems or AI EHS pedestrian detection hardware, CCTV AI Safety Systems don't rely on adding more devices to machines or people. Instead, they transform your existing camera network into a real-time AI-powered safety platform.

No new hardware, no forklift downtime, no wearables

CCTV AI Safety Systems connect directly to cameras already mounted in:

Warehouses

Docks

Yards

Aisles

Back-of-truck loading zones

Manufacturing cells

They deploy in days, not months. And because they're camera-based, they cover everyone:

Employees

Contractors

Visitors

Temp workers

Drivers

Vendors

A full-site safety intelligence layer

Zero wearables. Zero compliance challenges. Zero operator burden.

AI models continuously analyze:

Pedestrian–vehicle interactions

Unsafe behaviors

Line-of-travel violations

Congestion and dwell times

Blocked loading or staging zones

PPE compliance

Area-specific behaviors (ladder use, mounting trucks, overhead loads)

Slip/trip hazards

High-risk patterns across shifts

This transforms passive CCTV into the facility's digital nervous system: every camera becomes a sensor feeding real-time insight to EHS teams.

Predictive safety, not reactive alarms

Instead of simple collision alerts, the AI helps teams understand:

Why people enter forklift paths.

When congestion begins forming.

How workflow patterns create risk.

Where workarounds are becoming normalized.

Which behaviors repeat daily.

What conditions lead to SIF precursors.

It's a shift from "What happened?" to "What's about to happen?"

How CCTV-Based AI Safety Platforms Work

Step 1: Connect

The platform integrates with existing IP cameras and maps out:

High-risk intersections

Pedestrian corridors

Forklift routes

Docks and staging areas

Blind corners

Yard perimeters

This creates an immediate baseline of visibility.

Step 2: Deploy

AI models are configured for the facility's top safety risks, including:

Unsafe human-forklift interactions

Violations of pedestrian paths

Entry into restricted or hazardous zones

PPE compliance failures

Unsafe mounting/dismounting behaviors

Suspended load risks

Forklifts reversing into pedestrian areas

Queue and dwell time escalation

Slip, trip, and housekeeping hazards

Instant alerts notify teams of critical events.

Step 3: Protect

The AI continuously monitors behavior and conditions, automatically:

Scoring risk

Highlighting patterns

Finding root causes

Recommending corrective action

Showing context-rich video clips

Sending notifications based on severity

Delivering automatic shift/daily/weekly reports

This turns fragmented observations into a unified, always-on safety program.

"CCTV AI safety systems turn surveillance into foresight. And that foresight gives teams the power to prevent the preventable," according to Riodatos

Beyond Forklift Cameras and RFID:

Closing the Visibility Gap

CCTV AI Safety Systems do not replace forklift pedestrian detection systems or an on-vehicle forklift collision avoidance system. They complement them and close the visibility gaps that other systems cannot reach.

Forklift cameras have limited angles

On-vehicle AI cameras are powerful, but they:

Only see what's in front of the forklift

Get blocked by pallets

Shake, vibrate, or get dirty

Lose coverage when the forklift is parked

They protect the operator, not the environment.

RFID and UWB systems rely on human compliance

Footwear tags get forgotten. Visitors arrive without badges. Temporary staff skip tag distribution. RFID alone cannot deliver full coverage, especially in the busiest seasons.

CCTV AI sees what other systems simply cannot

It covers every forklift, not just one

It monitors every person, not only tagged workers

It reveals root causes, not just proximity

It detects behavioral drift

It identifies system-level patterns

Real-Time Operational Flow Intelligence

This is the missing piece that ties all safety technologies together.

CCTV AI isn't just about safety: it improves operational flow in ways traditional systems never could.

Movement clarity

Watch forklifts, doors, staging zones, and aisles update live. See flow issues as they arise.

AI-estimated dock completion times

AI predicts door completion based on activity and load movement.

This enables:

Faster staging

Cleaner hand-offs

Less idle equipment

Fewer unexpected delays

Dwell and queue time analytics

AI identifies:

Door congestion

Aisle bottlenecks

High dwell times

Queue buildup

These conditions often cause the unsafe pedestrian shortcuts and risky interactions EHS teams fight daily.

CCTV AI removes the guesswork.

AI-Powered Safety Intelligence: Turning Video into Foresight

This is where CCTV AI delivers particular value: not in detection, but in understanding.

Ask questions in natural language

Modern AI-driven safety platforms allow teams to ask:

"Show me last week's near misses around Dock 7."

"Where are pedestrians entering forklift zones most often?"

"What caused the congestion between 2 p.m. and 4 p.m.?"

"How did PPE compliance change this month?"

The AI instantly generates:

Dashboards

Heatmaps

Trend lines

Video summaries

Action recommendations

Video context = no more guesswork

Every unsafe moment comes with the why:

A blocked aisle forcing a shortcut

A forklift waiting idle too long

A pallet placed in a pedestrian path

A congested dock creating risky foot traffic

A team member repeatedly exposed to overhead loads

This clarity shortens investigations from hours to seconds.

Workers learn from their own behaviors

Empowering People, Reducing Complacency, Improving Culture

When people see themselves taking risky shortcuts, something shifts:

Awareness becomes self-correction.

Short clips replay the reality:

Stepping under suspended loads

Walking too close to moving forklifts

Forgetting a ladder

Entering an active loading zone

Skipping PPE during rush

Using the shortest path, not the safest

Teams begin coaching themselves. Supervisors stop micromanaging. Behavior change becomes natural, not forced.

A culture free of complacency

AI shows risks without blame. Workers respond with pride, not resistance. Safety becomes a shared responsibility.

This represents an important evolution in EHS:

AI provides the ongoing visibility

Rapid Deployment: From Installation to Insight in Days

CCTV AI Safety Systems work with:

On-premise networks

Hybrid cloud

Full cloud

And deploy extremely quickly:

Connect existing cameras

Configure rules and zones

Train models on site patterns

Begin receiving insights (usually within hours)

Most organizations start with a few cameras and expand to full-site coverage once they see the results. Learn more about implementation services.

The Future of AI in EHS

Predictive, Preventive, Human-Centric

Workplace safety is entering a new era: the early stages of a Fifth Industrial Revolution where AI partners with humans, rather than replacing them.

The future is clear:

AI handles the analysis

People handle the decisions

Together they prevent incidents that were once considered "unavoidable"

CCTV AI Safety Systems are increasingly becoming a key component of:

Forklift pedestrian detection programs

SIF prevention strategies

Real-time operations monitoring

Cultural improvement initiatives

Enterprise safety governance

The technology continues to evolve rapidly, with early adopters already seeing strong results.

"Safety improves not just when rules are enforced, but when risks are understood. AI makes that understanding continuous, unbiased, and actionable," according to Riodatos.

Conclusion: Visibility Determines Safety Outcomes

Every serious injury starts with a moment no one saw. CCTV AI Safety Systems reveal those moments. They turn blind spots into clear, actionable insight. They bring safety, operations, and culture into one connected view. And they give every team member (from the frontline to the executive) the clarity to prevent incidents before they happen.

When safety depends on visibility, CCTV AI Safety Systems deliver one of the most meaningful advancements available today. It is a truly meaningful step forward for workplace safety.

About Riodatos

Riodatos helps organizations across the U.S. integrate modern AI-based safety systems that transform existing cameras into real-time risk-detection and operational-visibility tools. We combine CCTV AI analytics with forklift pedestrian detection systems, forklift collision avoidance technologies, and forklift proximity warning system solutions to create safer, more efficient worksites.

Explore our solutions:

Learn more at riodatos.com

Quick Read Summary

CCTV AI Safety Systems for Workplace Visibility

👷♂️ In today's industrial environments, safety teams face one harsh truth: you can't prevent what you can't see. But new CCTV AI Safety Systems are changing the game by transforming passive cameras into real-time safety intelligence platforms.

--

🔍 Here's what you'll learn in the article:

🚧 Why even top safety programs still miss critical risks

🧠 How AI transforms CCTV into predictive safety intelligence

🔄 The power of real-time visibility (no new hardware required)

📊 Operational ROI: queue, dwell, and congestion analytics

💡 How AI empowers behavior change and strengthens safety culture

⚙️ Fast deployment (from connection to insights in just days)

🌍 Why AI-driven EHS is the future of workplace safety and efficiency

--

✅ These systems close the visibility gaps left by RFID tags, on-vehicle cameras, and manual audits and they give safety leaders the insights needed to prevent serious incidents before they happen.

--

👁️🗨️ AI safety isn't just about detection: it's about foresight, culture, and smarter operations.

--

Comments